Solder and End Feed Fittings from ValvesTubesFittings

BS EN 1057 Copper solder and end feed fittings from ValvesTubesFittings.com are all WRAS-approved and conform to BS EN 1254-1, these products are exceedingly popular in plumbing and heating installations today but this wasn’t always the case. When I joined this business 28 years ago we stocked Yorkshire brand solder ring and end feed fittings in copper. For many years we sold these mainly over our trade counter for those businesses collecting our more recognisable stock of malleable iron pipe fittings and at the time steel tubes to BS 1387:1985.

Our goals some years later changed and we discarded our stock of solder and end feed fittings. We decided to concentrate on our traditional threaded and welded fare in steel and stainless steel. But like many businesses the future is never written in stone and stockists and distributors must move with customer requirements. So, we returned to copper pipe and fittings probably a decade later.

Solder and End Feed Fittings a Wider Range

Since then we have increased our stock of solder and end feed fittings from a small stock of 15mm to 28mm to carrying solder fittings from 15mm to 54mm and end feed fittings in the same sizes. In addition, we have increased our stock of Table X Copper tubes to match what we carry in fittings.

The biggest change is the fact we abandoned our friends at Yorkshire Peglar due to the fact they offered little support, and their prices from our perspective were just too expensive. Our shelves are now filled with CUB brand copper solder and end feed fittings; as well as our range of brass compression fittings 15mm to 54mm also CUB Brand.

Solder and End Feed Fittings Change is in the Pipeline

Solder and end feed fittings from ValvesTubesFittings in copper are used in  many domestic and industrial installations. They are ideal where hot working is permitted and where adequate space allows for safe installation. They are used a great deal less on large installations as the skill level required to complete solder and end feed installations; is no longer an industry norm.

many domestic and industrial installations. They are ideal where hot working is permitted and where adequate space allows for safe installation. They are used a great deal less on large installations as the skill level required to complete solder and end feed installations; is no longer an industry norm.

Long pipe runs in larger bore copper are completed using M-profile press fittings. This is due to the time it takes to complete an installation and the fact they can be completed by a semi-skilled workforce. Both of these factors reduce greatly the cost of installation but also erode the skill level within the plumbing and heating industry.

This though is a self-fulfilling prophecy as the contracting industry has been forced for many years to reduce costs to win work. Resulting in less revenue available to employ staff on more traditional forms of apprenticeships. Thus, the erosion of skills across the industry will eventually reduce the skill base of the British plumbing and heating industry.

Copper Capillary (Solder Ring) Fittings

Copper capillary fittings are one of the traditional forms of plumbing used in many domestic installations. For those reading this who are not aware of what makes a capillary fitting, here is a quick explanation. The generic term for this type of copper product is a Yorkshire capillary fitting and the capillary element refers to a ring of solder integrated into each joint of the fitting. Industrial copper tubes in their present form for water systems did not begin until the 1930s; when modern mass production of copper tubes began. The capillary or solder ring fitting was patented by the Yorkshire Copper Works in 1934 and produced exclusively by them and their successors for 25 years. This exclusivity ended when the original patent expired but the name Yorkshire capillary has stuck.

plumbing used in many domestic installations. For those reading this who are not aware of what makes a capillary fitting, here is a quick explanation. The generic term for this type of copper product is a Yorkshire capillary fitting and the capillary element refers to a ring of solder integrated into each joint of the fitting. Industrial copper tubes in their present form for water systems did not begin until the 1930s; when modern mass production of copper tubes began. The capillary or solder ring fitting was patented by the Yorkshire Copper Works in 1934 and produced exclusively by them and their successors for 25 years. This exclusivity ended when the original patent expired but the name Yorkshire capillary has stuck.

Copper End Feed Fittings

The original copper fittings were of the flared variety connecting pipe easily and probably braised to withstand pressure. End-feed copper fittings arrived in the 20th century with lead solder which allowed the easy joining of copper pipe. Although at the time many homes were still supplied with water using lead pipes, despite it contaminating water supplies.

Lead could still be found in the solder used to join copper pipe for domestic water systems, though from 1985 potable water systems became completely lead-free with the introduction of lead-free solder fittings and lead-free solder for use with end feed fittings in copper. Both of which we offer here at ValvesTubesFittings.com.

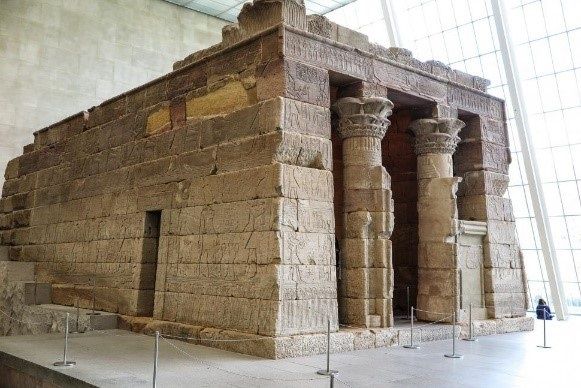

Ancient Copper Tube

The first known historical use of copper pipe but not  copper capillary was in the 5th Dynasty in ancient Egypt. Some 300 metres of copper drainage pipe was found in the Temple honouring King Sahure in Abusir Northern Egypt, following an archaeological dig in 1994. King Sahure reigned over his people from 2517 to 2505 B.C a mere 4522 years ago to date. The copper pipes were used to drain water away following ceremonies that presented food and offerings to the dead king in what was known as the Mortuary Temple.

copper capillary was in the 5th Dynasty in ancient Egypt. Some 300 metres of copper drainage pipe was found in the Temple honouring King Sahure in Abusir Northern Egypt, following an archaeological dig in 1994. King Sahure reigned over his people from 2517 to 2505 B.C a mere 4522 years ago to date. The copper pipes were used to drain water away following ceremonies that presented food and offerings to the dead king in what was known as the Mortuary Temple.

Despite these great advances by the Ancient Egyptians; the history of plumbing and water supply, is peppered with many different methods of water transportation. The Romans used lead pipes for drinking water installations and managed to poison very few. Because their water supplies had a high calcium content which coated the supply pipelines, protecting the people from lead poisoning.

In the 16th & 17th centuries in England water pipes were made from hollowed-out logs which were sealed with animal fats, the same method was used in the United States in the 19th century. The advance in using wooden pipework was made by using the same method employed to manufacture barrels, using metal straps to produce lengths of larger diameter tubes. Water mains were later done in cast iron which has been replaced with plastics in smaller sizes.

However, if you want to complete your water pipeline installation, we can offer the solution at ValvesTubesFittings.com. Although we have never been asked for it yet, as well as solder and end feed fittings from ValvesTubesFittings, we can offer whatever method is required; even if you request a wooden tube. For all your pipeline requirements, there is always ValvesTubesFittings.com.

Disclaimer: Information correct at the time of publishing (August 2017) but is subject to change. E&OE.

Get started in seconds!

Save your details, view past orders, and enjoy a faster checkout every time.