Cooking with Steam Precision and Control

Cooking with steam offers efficient precise temperature control and it can be used to create direct clean heat using steam injection, or it can be used via heat exchangers such as coils for traditional cooking and baking. Cooking with steam does not mean you need to fill a chamber or oven with direct steam, although if this is your method it does create beautiful restaurant-quality cuisine. Dry cooking is efficient but whether the heat comes from gas or electricity, it is essentially dry heat and not as easy to control precisely. The next paragraphs in our latest blog will explain why we believe steam is the answer to better flavours even for mass-produced food and drink products.

Cooking with Steam Culinary Steam

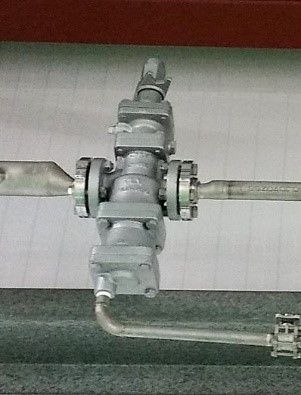

Clean, filtered steam offers an excellent source of controlled heat to produce exquisite-tasting food while adding and maintaining moisture content. Using steam control valves fitted with a cyclone separator in conjunction with a culinary-grade steam filter; maintains precise cooking temperatures. In addition, if the system is correctly sized to produce varying degrees of steam flow via pressure reduction; as stated moisture content can be measured and precise. If additional products like vortex steam flow meters are fitted, the steam content can be monitored by the operator.

Clean, filtered steam offers an excellent source of controlled heat to produce exquisite-tasting food while adding and maintaining moisture content. Using steam control valves fitted with a cyclone separator in conjunction with a culinary-grade steam filter; maintains precise cooking temperatures. In addition, if the system is correctly sized to produce varying degrees of steam flow via pressure reduction; as stated moisture content can be measured and precise. If additional products like vortex steam flow meters are fitted, the steam content can be monitored by the operator.

The obvious truth is maintaining moisture content when cooking produces better textures and preserves the natural flavour of the food being cooked. Drying many recipes results in poorer texture and reduced flavour; thus, denying the consumer the real pleasure of well-cooked dishes. Besseges (Valves, Tubes & Fittings) Ltd has spent many years working with contractors and end users to produce better outcomes using process steam. In recent years we have worked with many sectors of the food industry to create better conditions for cooking with steam.

Cooking with Steam Boiling Pans and Steam Coils

When cooking with steam, whether using culinary steam or heat exchangers, precise temperatures can be maintained; this is especially true in multistage cooking. That is when the product or recipe requires rapidly bringing to temperature initially then a lower temperature is required to complete the cook. Process steam with the right controls can achieve a higher temperature quickly and then reduce the temperature by reducing the pressure.

This is because the pressure and temperature of saturated steam are consistent, by looking at the curve of saturated steam on a graph the temperatures are precise. For example, saturated steam at 2 bar is 133.7°C and steam tables can be used to ascertain the temperature at varying pressures. Lower-pressure steam is more efficient to cook with as the specific enthalpy increases as the pressure increases.

This is because the pressure and temperature of saturated steam are consistent, by looking at the curve of saturated steam on a graph the temperatures are precise. For example, saturated steam at 2 bar is 133.7°C and steam tables can be used to ascertain the temperature at varying pressures. Lower-pressure steam is more efficient to cook with as the specific enthalpy increases as the pressure increases.

Using steam tables, it is possible to predict heat transfer rates; and if you aren’t comfortable with the concept. Contact your local expert in process steam to discuss the process in hand or even arrange a site visit; which is often most efficient. This is often true due to the fact problems and issues on process steam can arise from installation errors. There can be many reasons that can cause increased water hammer, poor temperature control and incorrectly sized steam traps and or control valves. It is often the case that a critical eye can see issues not considered, often down to lack of knowledge and experience.

Once a cooking vessel is running at its most efficient, product quality can increase, and cooking times reduced. With the right control and or pressure-reducing valve technology, steam usage can be reduced by up to 9% due to greater heat transfer efficiency.

Cooking with Steam Control Valves

There are many control valves on the market for cooking with steam and sizing  them is relatively simple to do. By working out the maximum heat load required that fits the heating times of one or multiple recipes for a vessel the correctly sized control valve can be arrived at. The most precise control valves for cooking with steam in our experience are electro-pneumatic units, which are available through us from many manufacturers.

them is relatively simple to do. By working out the maximum heat load required that fits the heating times of one or multiple recipes for a vessel the correctly sized control valve can be arrived at. The most precise control valves for cooking with steam in our experience are electro-pneumatic units, which are available through us from many manufacturers.

We can offer too many to mention in a single blog, but in the main, we tend to offer TLV, Samson and Genebre products; though not exclusively. Our preference in recent times has been the latest TLV control valves for steam; the CV-COSR and the CV-COS. The key to ensuring high-quality steam and great heat transfer though isn’t just about the valves themselves. Just as important is the installation of the product and ensuring that either a correctly sized and positioned dirt pocket with steam traps are installed; or that a control valve has the facility for a built-in steam trap or an outlet where one can be fitted. The next paragraphs will explore the two products we have mentioned and why we believe they should be considered.

Cooking with Steam TLV CV-COS Control Valve

The TLV CV-COS control valve should be top of the list for cooking with steam, the precise control and excellent quality steam should make it a food industry staple. Here is the basic information from TLV about their CV-COS product and the advantages it offers.

- Built-in cyclone separator and free float steam trap producing dryer higher quality process steam

- Removal of condense while the valve is closed thus reducing the possibility of water hammer

- Compact pneumatic actuator with digital I/P positioner

- Rolling actuator diaphragm maximises service life

- Improved control at low flow and tight shutoff due to self-adjusting positioner

- Positioner LCD allows simple operation with capacitive keys, displaying valve aperture and error codes

- Self-adjusting chevron packing minimizes seal leaks, stem wear and stiction/hysteresis problems

Our first experience using this product was to solve cooking issues on two oat cookers, the original installation had two separate control valves to achieve a two-stage cook. In addition to the standard control valve for this installation, we added a pressure transmitter to control the differing steam pressures required and since this installation have done similar at other businesses.

The fact is what was achieved meant a system that often failed was brought up to date and improved. In more recent quotes, we have offered the same to improve outcomes on a pasteurizer, which will not only achieve improved production outcomes, but it will reduce the amount of steam used to get there. So, if you have a process cooking with steam, please contact our technical sales team to discuss whether it can be improved.

Cooking with Steam TLV CV-COSR Control Valve

Cooking with steam using a TLV CV-COSR control valve has one distinct difference to the CV-COS, that is the CV-COSR does not have a built-in separator. The function and efficiency of the control valve are the same; it just lacks the separator which improves heat transfer. What is unique to this control valve over other manufacturers is an outlet at the base of the valve allows for a TLV free float steam trap to be connected, this prevents condense collecting in the control valve when it is closed, thus reducing water hammer and erosion.

What is unique to both these options is a dirt pocket with steam trap is not required before either of these control valves. If you have a set-up that does not have a dirt pocket close by, the risk is the service life is reduced and maintenance and downtime are increased. Allowing condense to collect before a closed control valve can cause issues that can’t be seen.

Cooking with Steam Process Efficiency

Erosion within a process steam system is a normal part of its daily running,  reducing this reduces downtime and maintenance. In addition, the prevention of water hammer problems is something that should be part of every steam installation. Not only for the obvious reduction in maintenance time but for health and safety reasons as well, water hammer can be dangerous to those working on or around a steam system; due to the damage it can cause.

reducing this reduces downtime and maintenance. In addition, the prevention of water hammer problems is something that should be part of every steam installation. Not only for the obvious reduction in maintenance time but for health and safety reasons as well, water hammer can be dangerous to those working on or around a steam system; due to the damage it can cause.

For more information on cooking with steam or any of your processes, talk to us, the only authorised TLV distributor in the North of England. We can offer simple, practical advice on best practices as well as help sizing steam traps, and control and pressure-reducing valves. More than this we can look at stall issues on heat exchangers, providing long-term economic solutions; and offer other solutions on condense recovery and flash recovery incorporating steam compressors. Talk to a member of our sales team today to see how your process steam system can be improved and or made more energy efficient; we look forward to hearing from you.

Disclaimer: Information correct at the time of publishing (February 2018) but is subject to change. E&OE.

Get started in seconds!

Save your details, view past orders, and enjoy a faster checkout every time.