How Can I Improve My Process Steam System?

The question “How can I improve my process steam system?” has been asked for over a century, from the days of the first uses of steam in the textile industry, companies and individuals have sought ways to improve heat transfer and the carriage of steam. We have seen many improvements and changes to technology over many decades from many companies including TLV, Spirax Sarco, Gestra and many others too numerous to mention, although in recent years I have seen a 1923 Hopkinson steam trap still in service and our customer is now in possession of a copy of the original data sheet despite its great age.

Now returning to the question of how can I improve my process steam system, the simple answer is really to listen to individuals and businesses that have the knowledge and experience to aid you in this task. Steam specialists like us have an array of products and information that will achieve greater process efficiency and heat transfer improvements.

As one of the UK’s leading TLV distributors, we have the products in stock to offer the solution you’re looking for and the answers from vast experience to understand why the solutions we put forward are the right thing to do. Please continue reading this blog for more information or contact our excellent technical sales team to discuss your problem or requirement.

How Can I Improve My Process Steam System? Dirt pockets

The removal of condense is hugely important to process steam efficiency and this can be achieved in a number of ways, one of the most important is dirt pockets in steam systems. For those who are not aware of what a dirt pocket is, we will explain and this is truly one of the most important answers to the question of how can I improve my process steam system.

Dirt pockets are vertical tubes positioned on a steam main which allow condense and debris to collect, these should be line-sized in the vast majority of steam systems, this certainly applies to mains up to and including 150mm (6”) nominal bore. If a dirt pocket is correctly sized then the measurement from the centre of the steam main to the bottom of the dirt pocket should be 500mm. The condense outlet tube should be installed 400mm centre to centre with the steam main and in addition, the outlet tube should have a fall installed made up of two 90° elbows, in addition, we also recommend the installation of a discharge valve at the base of the dirt pocket, usually connected using a tapped blank flange.

The correct installation of dirt pockets ensures that non-discharged condense is removed efficiently, shallow dirt pockets will cause issues on startup and pockets that are not the correct bore size will allow non-discharged condense to pass over them and remain in the steam system. The latter is something we come across on several steam systems, usually where the installer or contractor has a limited understanding of process steam installations.  Here at Besseges (Valves, Tubes & Fittings) Ltd we always recommend using competent and experienced installers on steam systems as mistakes can be costly and sometimes catastrophic.

Here at Besseges (Valves, Tubes & Fittings) Ltd we always recommend using competent and experienced installers on steam systems as mistakes can be costly and sometimes catastrophic.

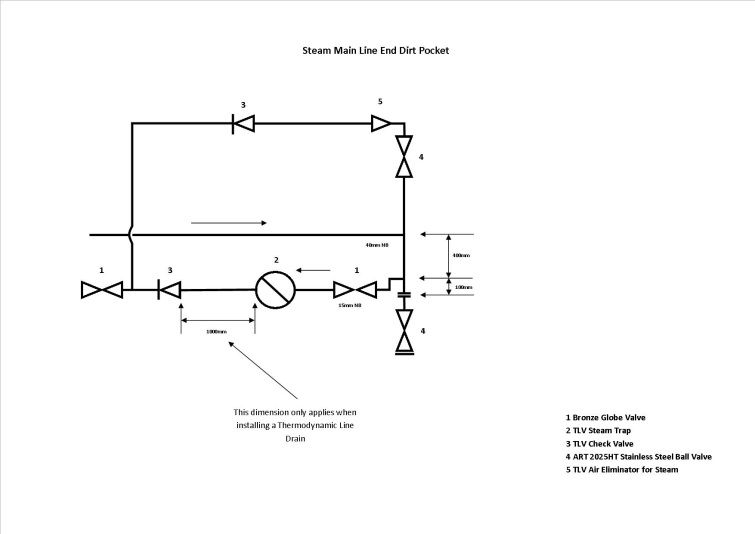

Returning to the subject of dirt pockets, in particular, there are three different types of dirt pockets; they are in line, relay point and line end dirt pockets. Inline dirt pockets are installed on a horizontal steam main; relay points are installed at points where the level of the system changes and line ends are obvious. The inline and relay point dirt pockets are set up the same with a steam trap set made up of a correctly sized steam trap usually a TLV Free Float line drain or a Thermodynamic type, then two stop valves, a non-return valve and an optional sight-glass. The line end dirt pocket has everything that the other two types have with an additional TLV air eliminator, stop valve and non-return valve.

Please see the illustration for more information or contact our technical sales team to discuss your particular installation. The simple fact is a poorly installed dirt pocket of any type is neither use nor ornament; they are there to reduce water hammer issues and erosion within your steam system, shallow dirt pockets do not prevent water hammer, and incorrect bore size allows non-discharged condense to remain in the system, badly sized or specified steam traps cause startup issues and leaving out the air eliminators on line ends allows air to be trapped increasing start-up times.

It must be noted though that dirt pockets only remove non-discharged condense within the steam system, to remove entrained condense that is condense travelling within the steam flow a different method must be employed, the next section will cover this topic as part of our how can I improve my process steam system blog.

How Can I Improve My Process Steam System? Cyclone separators

As we said at the end of the last topic entrained condense cannot be removed using dirt pockets and we have found the best way of achieving this is to install a TLV cyclone separator. TLV cyclone separators remove up to 98% of entrained condense and can improve heat transfer efficiency by around 9%. Improvements in heat transfer increase process efficiency and reduce costs, the removal of entrained condense reduces the associated erosion reducing long-term maintenance costs.

As we said at the end of the last topic entrained condense cannot be removed using dirt pockets and we have found the best way of achieving this is to install a TLV cyclone separator. TLV cyclone separators remove up to 98% of entrained condense and can improve heat transfer efficiency by around 9%. Improvements in heat transfer increase process efficiency and reduce costs, the removal of entrained condense reduces the associated erosion reducing long-term maintenance costs.

With all these advantages you’d think that every process steam system would have more than one of these installed but the truth is businesses still look at short-term costs, i.e., initial purchase and installation costs. Long-term erosion costs will be in the next years or the year after accounts and an increase in heat transfer efficiency is just jargon from the business trying to sell me the product. This is usually the point when the site engineer regards the accountant with a look of resignation knowing that in the future they will pay a heavy price for this missed opportunity. The truth is that business needs to find suppliers and contractors they trust to answer the question of “How can I improve my process seam system?”

How Can I Improve My Process Steam System? Final thought

Many more ways to answer this long-asked question and we are always ready to discuss them with existing and new customers,  we find that working with businesses through discussion and often site visits expands our knowledge and improves what we can offer. Many solutions are often as plain as the nose on your face but sometimes it takes a new perspective to see through the fog. Good suppliers and contractors will bring you solutions that are right for your business and long-term relationships with them will lead to trust as is the case with many of the end users and contractors we supply at present.

we find that working with businesses through discussion and often site visits expands our knowledge and improves what we can offer. Many solutions are often as plain as the nose on your face but sometimes it takes a new perspective to see through the fog. Good suppliers and contractors will bring you solutions that are right for your business and long-term relationships with them will lead to trust as is the case with many of the end users and contractors we supply at present.

Here at Besseges (Valves, Tubes & Fittings) Ltd we don’t spout jargon but offer solutions at the right price, whether you trust our business to do the right thing is learned through experience. We hope that we can answer your question on your process steam system now and in the future and look forward to showing you what we can do for your business. Please contact us or take a look at some of our other blogs on process steam, we are certain we can answer the question of how can I improve my process steam system.

Disclaimer: Information correct at the time of publishing (February 2016) but is subject to change. E&OE.

Get started in seconds!

Save your details, view past orders, and enjoy a faster checkout every time.