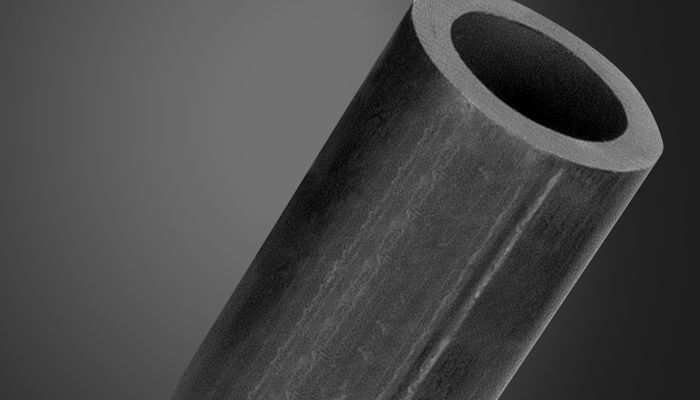

Hot Finished Seamless Tube ASTM A106

Welcome to another blog from ValvesTubesFittings.com, the subject of today’s post is ASTM A106 hot-finished seamless tube. This product range is also known as line piping, quality tube and many other names, although the latter could be used to describe what we offer across all tubular products could carry the same description. The reason this particular subject was chosen is the fact that our webmaster required more information to publish on this range, so you see, these are never random choices. My job as the author of our blogs is to provide the detail, while at the same time increasing the likelihood of your searches finishing up with our websites as a result.

For the most part, blogging on our websites covers the story of our products and sometimes the community we live and work in. Many of our recent blogs, as far as product is concerned have been off the mark. So this piece is a return to our core stock products and how they can complete the work you have in hand, and a return to products of quality which is far better than just ‘acceptable’. we aim to offer hot-finished seamless tube ASTM A106 to the highest possible standard. Of course, though we must also offer quality and longevity at an affordable price and as with all we offer, traceability is at the heart of our supply.

For more information on ASTM A106 hot-finished seamless tube. Please continue reading this blog or contact our excellent sales team. I hope as always that you have chosen the former and have not yet clicked to contact our sales staff. The following paragraphs will give you a great deal of product information, and as always with my blogs a little of the history behind the product. Although you don’t really need to know where and how a product began, I believe it just adds to the conversation.

Hot Finished Seamless Tube Pertinent Flanges

As with much of what we supply at ValvesTubesFittings.com hot finished seamless tube to ASTM A106 Grade B is one of many products; which are used in conjunction with other products. Installing hot-finished seamless tubes requires pipe fittings and flanges to ensure that the pressure and temperature requirements of the system are met. Where flanges are concerned the type used depends on which country you are currently reading this from.

tube to ASTM A106 Grade B is one of many products; which are used in conjunction with other products. Installing hot-finished seamless tubes requires pipe fittings and flanges to ensure that the pressure and temperature requirements of the system are met. Where flanges are concerned the type used depends on which country you are currently reading this from.

If for instance you are in the United States and reading this blog, your go-to flanges are going to be ANSI/ASME products. Pressure and temperature will decide which particular ANSI/ASME flange is required. From a stock perspective here at ValvesTubesFittings.com, we carry in stock ANSI/ASME class 150 and 300 raised-faced slip-on flanges, as well as weld-neck and blind flanges. From a European perspective, the norm would be BS EN 1092-1:2018 flanges, available in various pressures. These range from PN2.5 to PN64 and again quoting stock items we carry from PN6 to PN40 on the shelf. For 65mm nominal bore DIN flanges, we offer BS EN 1092-1:2007 which is a four-hole version.

Hot Finished Seamless Tube ASTM A106 Fittings to Suit

Our range of welding fittings suitable for use with ASTM A 106 Grade B hot finished seamless tube; are available from stock in sizes from 15mm (1/2″) nominal bore to 400mm (16″) nominal bore. We have also provided customers with fittings as large as 900mm (36″), tube product for larger sizes is usually listed as API 5L Grade B tubes and can be found in welded and seamless versions.

The welding fittings suitable for ASTM A106 grade B hot finished seamless tube are, at the time of writing to ASME B16.9-2018, and are available in various wall thicknesses. For carbon steel pipework systems the norms are schedule 40, standard weight, schedule 80, extra strong, schedule 160 and double extra strong. Each increase in number or description denotes an increase in wall thickness and all have a corresponding hot finished seamless tube or welded tube. All materials in this product group are fully traceable and supplied with 3.1 test certificates.

Hot Finished Seamless Tube on Process Steam Lines

We supply a great deal of ASTM A106 grade B hot-finished seamless tubes for carrying process steam. As a business, we have supplied this product with the correct steam valves, controls and traps for nearly three decades. Our business has supplied steam products including tubes and fittings to businesses from Aberdeen to Plymouth. We have supplied hot-finished seamless tubes for many different manufacturers including breweries, energy, food manufacturing, pet food sites, rubber processing, textiles and many more. To ensure you are using the correct size of hot finished seamless tube, visit our Downloads and Calculators page to use the TLV Toolbox.

Hot Finished Seamless Tube a Short History

The first time we see a consistent standard applied to the manufacture of the hot-finished seamless tube was in 1928 with API 5L:1928, the first edition of this standard; at the time of writing I believe we are now on the 46th edition; API 5L:2018. API is the American Petroleum Institute and was formed in 1924 to standardise specifications across the petroleum industry.

ASTM though predates the American Petroleum Institute by thirty years and was the American Society for Testing and Materials, it was a scientific and engineering group led by Charles Dudley. They are now ASTM International and are still based in the town of West Conshohocken Pennsylvania. Their site lists ASTM A106 hot-finished seamless tube but does not provide information on when their first standard was introduced. So at present, the first standard applied to hot-finished seamless tubes that we are aware of was API5L:1928.

Hot Finished Seamless Tube always needs a Valve

Clearly, as a valve and pipeline supplier, we offer a comprehensive range of valves suitable for numerous applications. For small bore pipeline systems in 15mm (1/2″) to 50mm (2″), we have a wide range of good quality threaded valves covering a wide range of pressures and temperatures. If you are using a high-quality hot-finished seamless tube to ASTM A106 grade B, then the valve quality should match it. The following valves are available from our website in the threaded variety:

Gate Valves

Globe Valves

Non-Return Valves (Check Valves)

Ball Valves

Bellows Sealed Stop Valves

For larger and small bore systems we also offer the same range of valves in flanged versions. We can provide valves with EN 1092-1 flanges, ASME/ANSI flanges and when required BS10 flanges. If you have found this blog on hot-finished seamless tubes of interest your feedback would be greatly appreciated. This can be done by visiting our contact our sakes team section; who are also available to assist you with your order.

Disclaimer: Information correct at the time of publishing (March 2019) but is subject to change. E&OE.

Get started in seconds!

Save your details, view past orders, and enjoy a faster checkout every time.