TLV COS-R Pressure Reducing Valves Available From Stock

ValvesTubesFittings.com can now offer the full range of flanged TLV COS-R pressure reducing valves in GGG40 ductile cast iron 15mm to 50mm. In addition, the 15mm to 25mm BSP threaded version is also available for delivery to suit your requirements. This high-quality versatile pressure reducing valve for steam is one of the market leaders due to design quality and service life.

ValvesTubesFittings.com can now offer the full range of flanged TLV COS-R pressure reducing valves in GGG40 ductile cast iron 15mm to 50mm. In addition, the 15mm to 25mm BSP threaded version is also available for delivery to suit your requirements. This high-quality versatile pressure reducing valve for steam is one of the market leaders due to design quality and service life.

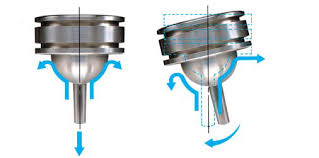

The TLV COS-R pressure reducing valve has a unique curved piston which deflects water hammer and is self-centring, ensuring exceptional control of pressure and steam flow. Outstanding research and design from TLV guarantee high-quality products and quality controlled manufacturing is the benchmark that allows us to sell and specify with confidence for all their process steam products. For more information on this product please continue to read this Blog or alternatively contact our sales team to discuss your requirement.

TLV COS-R Pressure Reducing Valves Specification

When installing steam products a degree of understanding of the uniqueness of process steam is a boon. Here at ValvesTubesFittings.com, we can assist you if you’re not 100% on the correct procedures. The TLV COS-R pressure reducing valve is a precision instrument that must be installed in the right way, this really applies to any process steam pressure reducing valve no matter which manufacturer you use. Improper installation will result in poor outcomes on your steam system; this can only result in less efficient production.

When installing steam products a degree of understanding of the uniqueness of process steam is a boon. Here at ValvesTubesFittings.com, we can assist you if you’re not 100% on the correct procedures. The TLV COS-R pressure reducing valve is a precision instrument that must be installed in the right way, this really applies to any process steam pressure reducing valve no matter which manufacturer you use. Improper installation will result in poor outcomes on your steam system; this can only result in less efficient production.

When working out your steam flow consult the manual of the heat exchanger in question or if this is not available take a good look at the existing pipe sizing to ascertain maximum steam flow. Once you are aware of the steam flow required or available look to sizing a TLV COS-R pressure reducing valve around 20% above the maximum flow rate required. At the point where you are happy with the sizing of the TLV COS-R pressure reducing valve look at the right way of completing the installation.

We advise that a strainer and stop valve is always installed ten pipe diameters prior to the eccentric reducer adjacent to the COS-R then another stop valve is installed 15 pipe diameters after the eccentric reducer on the outlet side. Please note we always recommend that when installing a pressure reducing valve that eccentric reducers are always used, this greatly reduces water hammer issues associated with concentric reducing fittings.

Prior to the inlet stop valve and after the outlet stop valve pressure gauges should be installed and of course, a safety valve to protect vulnerable equipment after the final stop valve/pressure gauge. Other considerations should be the correct sizing of the inlet and out pipework based on maximum steam flow, help with this can be found by using the TLV Calculator by following the highlighted link or by contacting our technical sales team. We have added a quick sketch to illustrate a typical TLV COS-R pressure reducing valve installation as a guide.

Disclaimer: Information correct at the time of publishing (January 2016) but is subject to change. E&OE.

Register today for access to our extensive product range

Register today for access to our extensive product range